Variable-Frequency Drives 2024:- also referred to as an Adjustable-Frequency Drive (AFD) or Inverter Drive, is a motor controller designed to regulate the speed and torque of an electric motor by adjusting the frequency and voltage supplied to it. Essentially, it enables the precise control of an electric motor’s speed.

Topics Cover In This Post

- 1 Enhancing Energy Efficiency with Variable Frequency Drives: A Comprehensive Guide

- 2 What is Variable-Frequency Drives?

- 3 Understanding About Variable Frequency Drives (VFDs)

- 4 Applications of Variable Frequency Drives

- 5 Introduction to Variable Frequency Drive (VFD)

- 6 How Variable Frequency Drives Work

- 7 Benefits of Using Variable Frequency Drives

- 8 Applications of Variable Frequency Drives

- 9 Choosing the Right Variable Frequency Drive

- 10 Installation and Setup of Variable Frequency Drives

- 11 Common Issues and Troubleshooting

- 12 Maintenance Tips for Variable Frequency Drives

- 13 Future Trends in Variable Frequency Drive Technology

- 14 Case Studies: Successful VFD Implementations

- 15 Regulatory Compliance and Standards

- 16 Comparisons with Other Motor Control Technologies

- 17 Environmental Impact of Variable Frequency Drives

- 18 Expert Opinions and Testimonials

- 19 Conclusion

Enhancing Energy Efficiency with Variable Frequency Drives: A Comprehensive Guide

Introduction:

In today’s rapidly evolving industrial landscape, the optimization of energy consumption is imperative for sustainability and cost-effectiveness. Variable Frequency Drives (VFDs) play a crucial role in achieving these objectives. This article aims to delve into the significance of VFDs, their applications, and effective SEO-friendly strategies to boost visibility and accessibility.

What is Variable-Frequency Drives?

A Variable-Frequency Drive (VFD), also referred to as an Adjustable-Frequency Drive (AFD) or Inverter Drive, is a motor controller designed to regulate the speed and torque of an electric motor by adjusting the frequency and voltage supplied to it. Essentially, it enables the precise control of an electric motor’s speed.

VFDs are widely employed in industrial and commercial settings to enhance energy efficiency, provide accurate motor speed control, and reduce mechanical wear and tear. By manipulating the frequency of the Electrical supply to the motor, VFDs can effectively manage motor speed, influencing the output of connected equipment such as pumps, fans, compressors, and conveyor systems.

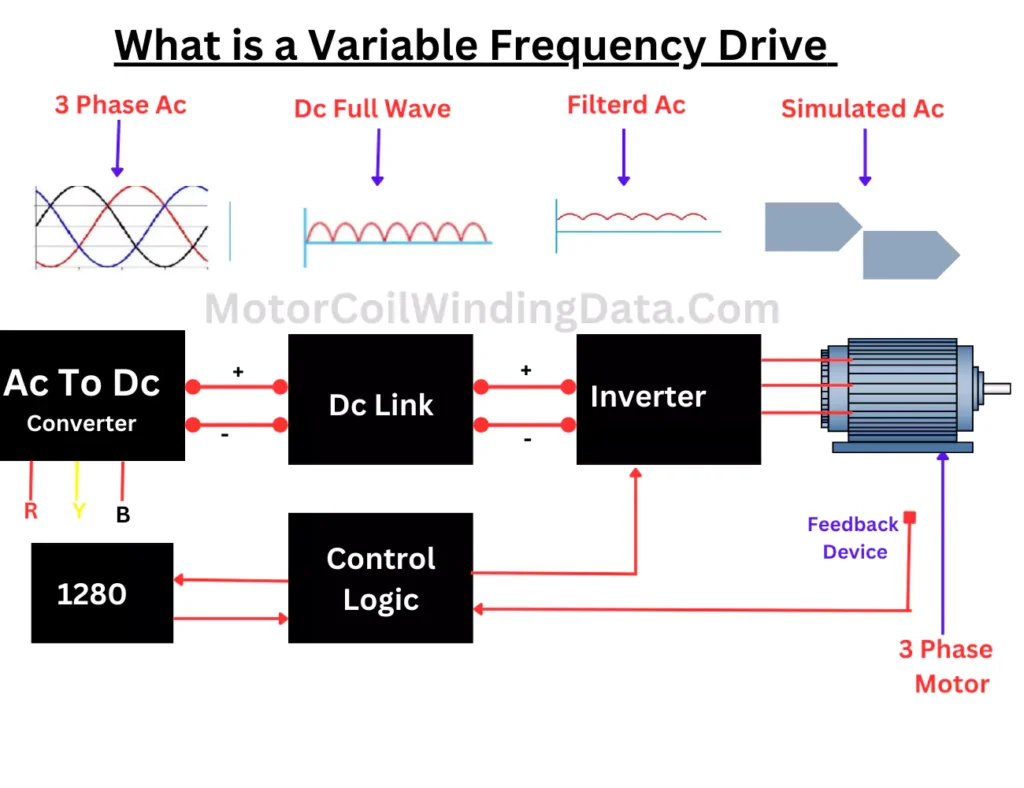

The essential components of a Variable-Frequency Drive include a rectifier (which converts AC power to DC), a DC bus, an inverter (which converts DC power back to variable-frequency AC power), and a control system overseeing the overall operation of the drive. VFDs play a crucial role in contemporary automation systems, contributing to optimized energy consumption and improved efficiency in motor-driven systems.

You May Also Search What Is Motor Winding? variable frequency control of induction motor.

Understanding About Variable Frequency Drives (VFDs)

Variable Frequency Drives, also known as adjustable speed drives, represent electronic devices that regulate the speed and torque of an electric motor by adjusting the frequency and voltage supplied to it. This technology finds widespread adoption across various industries due to its capability to enhance energy efficiency, reduce maintenance costs, and extend the lifespan of equipment.

Applications of Variable Frequency Drives

Explore the diverse applications of VFDs in industries such as manufacturing, HVAC systems, water treatment plants, and more. Include specific case studies and success stories to underscore the tangible benefits of implementing VFDs in different settings.

What Is The Advantages of Variable Frequency Drives

Outline the key advantages of VFDs, encompassing energy savings, precise process control, reduced wear and tear on machinery, and compliance with environmental regulations. Emphasize the role of VFDs in achieving sustainability goals and lowering carbon footprints.

- Choosing the Right Variable Frequency Drive

- Motor Compatibility

- Power Requirements

- Control Options

- Installation and Setup of Variable Frequency Drives

- Common Issues and Troubleshooting

- Overheating

- Voltage Fluctuations

- Harmonics

- Maintenance Tips for Variable Frequency Drives

- Future Trends in Variable Frequency Drive Technology

- Case Studies: Successful VFD Implementations

- Regulatory Compliance and Standards

- Comparisons with Other Motor Control Technologies

- Environmental Impact of Variable Frequency Drives

- Expert Opinions and Testimonials

- Conclusion

Variable Frequency Drives: Revolutionizing Motor Control

In the fast-paced world of technology, the need for efficient and adaptable motor control solutions has never been more crucial. One such innovation making waves is the Variable Frequency Drive (VFD). Let’s delve into the world of VFDs, understanding their workings, benefits, applications, and much more.

Introduction to Variable Frequency Drive (VFD)

Variable Frequency Drives, commonly known as VFDs or AC drives, are electronic devices designed to control the speed and torque of an electric motor. These drives have become indispensable in various industries due to their ability to optimize energy consumption and enhance overall motor performance.

How Variable Frequency Drives Work

At their core, VFDs modify the frequency and voltage supplied to an electric motor, allowing precise control over its speed and output. By adjusting these parameters, VFDs enable smooth acceleration, deceleration, and operation at varying speeds, contributing to energy efficiency and reduced wear and tear.

Benefits of Using Variable Frequency Drives

Energy Efficiency

One of the primary advantages of VFDs is their contribution to energy efficiency. These drives ensure that the motor operates at the optimal speed, eliminating unnecessary energy consumption during low-demand periods.

Cost Savings

The energy savings achieved with VFDs directly translate into cost savings for businesses. Reduced wear on the motor also leads to extended equipment life, further adding to the economic benefits.

Motor Protection ?

VFDs provide effective motor protection by controlling factors like voltage, current, and temperature. This results in enhanced motor lifespan and reduced maintenance costs.

Applications of Variable Frequency Drives

Industrial Sector

VFDs find extensive use in industrial applications, facilitating precise control over machinery in manufacturing processes. This not only enhances productivity but also reduces the environmental impact of excessive energy consumption.

HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, VFDs enable variable fan speeds, ensuring optimal climate control and energy efficiency. This is particularly crucial in large commercial buildings.

Pump Control

VFDs are instrumental in pump control, allowing for variable flow rates based on demand. This is beneficial in scenarios where constant speed pumps would be inefficient.

Choosing the Right Variable Frequency Drive

Selecting the appropriate VFD involves considering factors such as motor compatibility, power requirements, and control options. Matching the drive to the specific needs of the application is essential for optimal performance.

Motor Compatibility

Ensure that the VFD is compatible with the type of motor being used. Different motors may require specific drive features for seamless integration.

Power Requirements

Understanding the power requirements of the application helps in selecting a VFD with the appropriate capacity. Oversizing or undersizing can lead to inefficiencies and potential issues.

Control Options

Evaluate the control options provided by the VFD, considering the ease of integration with existing systems and the level of customization required.

Installation and Setup of Variable Frequency Drives

Proper installation and setup are critical for the effective functioning of VFDs. Adhering to manufacturer guidelines and seeking professional assistance can prevent issues and ensure a smooth operation.

Common Issues and Troubleshooting

Despite their benefits, VFDs may encounter issues such as overheating, voltage fluctuations, and harmonics. Understanding these common problems and implementing effective troubleshooting measures is essential.

Overheating Problem

Overheating can occur due to inadequate ventilation or overloading. Regular maintenance, proper cooling systems, and monitoring can prevent overheating issues.

Voltage Fluctuations Up & Down

Voltage fluctuations can affect the stability of VFDs. Installing voltage regulation systems and surge protectors can mitigate this risk.

Harmonics

Harmonics, unwanted electrical frequencies, can impact VFD performance. Filters and additional harmonic mitigation devices may be required for optimal operation.

Maintenance Tips for Variable Frequency Drives

Routine maintenance is crucial for ensuring the longevity of VFDs. Regular inspections, cleaning, and addressing issues promptly contribute to reliable and efficient operation.

Future Trends in Variable Frequency Drive Technology

The future of VFD technology holds exciting possibilities, including advancements in digital controls, improved diagnostics, and increased integration with smart systems for enhanced automation.

Case Studies: Successful VFD Implementations

Explore real-world examples of industries and businesses benefiting from the implementation of VFDs, showcasing the diverse applications and positive outcomes.

Regulatory Compliance and Standards

Understanding and complying with industry standards and regulations is vital for ensuring the safe and effective use of VFDs. Stay informed about the latest updates to avoid potential legal and operational challenges.

Comparisons with Other Motor Control Technologies

While VFDs offer numerous advantages, it’s essential to compare them with other motor control technologies to make informed decisions based on specific application requirements.

Environmental Impact of Variable Frequency Drives

Assess the environmental impact of using VFDs, considering factors such as energy savings, reduced carbon footprint, and sustainable manufacturing practices.

Expert Opinions and Testimonials

Gain insights from industry experts and users who have experienced the benefits of VFDs firsthand. Their perspectives provide valuable information for those considering the adoption of this technology.

Conclusion

In conclusion, Variable Frequency Drives have transformed the landscape of motor control, offering unparalleled benefits in terms of energy efficiency, cost savings, and performance optimization. As industries continue to embrace this technology, the future holds promising advancements, making VFDs a cornerstone of modern motor control solutions.

FAQs: Variable Frequency Drives

How do VFDs contribute to energy savings in HVAC systems?

VFDs enable variable fan speeds in HVAC systems, optimizing energy consumption by adjusting the fan speed based on the required climate control.

Are VFDs compatible with all types of electric motors?

VFD compatibility depends on the specific features and requirements of the electric motor. It’s essential to match the characteristics for seamless integration.

What measures can be taken to prevent overheating issues in VFDs?

Regular maintenance, proper

Can VFDs be retrofitted into existing industrial setups?

Yes, VFDs are often retrofitted into existing setups to enhance control and energy efficiency. However, careful consideration of compatibility is necessary.