All Types Of Motor Winding:– In simple Language When we give Electric current to an Electrical motor, then a magnet is made in it and the help of the same magnet rotates the motor rotor. This makes it possible with the help of Motor Winding And the next question is that What Is Motor Winding. In this post, we are also describing All Types of Electrical Motor Winding, and Different Types of Motor winding. What Is A Motor Winding?| All Types Of Motor Winding | Motor Winding Explain.

Topics Cover In This Post

- 1 What Is A Motor Winding?

- 2 Motor Winding?

- 3 How Motor Rotates The Rotor.

- 4 Motor Winding & Its Type Ac Dc Motor.

- 5 What is Armature Winding?

- 6 Whats Is Dc Motor Winding.

- 7 Single Phase And Three Phase Motor Winding.

- 8 How To Run 3 Phase Motor On Single Phase Supply.

- 9 Three Phase Motor On Single Phase Supply Video Watch Here.

What Is A Motor Winding?

First Of All, Let Me Explain What is Motor winding. It is a conductive wire, that is situated in a circle design that conveys electrical flow. At the point when a current-conveying transmitter is orchestrated along these lines, an attractive field is created through the escape clause, and the more circles you make with the wire, (the more “windings”) the more grounded the attractive field.

Two excellent instances of the utilization of Motor Windings are in transformers and engines. For your situation, an engine winding, or all the more actually, an armature, is the piece of the engine that is liable for creating the attractive field to make the rotor turn.

In material Engineering Technology, on the off chance that you have a current-conveying conductor, and you place that conductor almost an attractive field, you will put a force on the said conductor.

This implies you have two current-conveying conductors, one to create an attractive field (the windings), and the other is getting the field and which at that point actuates a current during that time conductor. Presently you have what you have to produce force, which pivots the rotor.

Motor Winding?

The motor winding represents the electrical conductor winding in the motor between the housing and the rotor. The conductor consists of a wire with high electrical conductivity and can be used in different thicknesses.

Electrical Motor Winding Video Watch Here.

How Motor Rotates The Rotor.

In An Simple Electrical Motor, you have the Stator and Motor. In a Universal Split stage Motor, you have both the Stator windings and Motor windings being provided with a voltage. The Stator windings are circles of wire which when provided produce an attractive field.

The Motor winding likewise comprises of circles of wire, two sets typically, one thicker than the other to cause a stage move in the voltage being provided. This engine wrapping sets up a field that communicates with the Stator field, producing a force.

Either a commutator or slip ring is utilized to keep the voltage throbbing between the two engine windings in synchronization.

Motor Winding & Its Type Ac Dc Motor.

The windings utilized in pivoting Simple electrical Motors To Rotating can be named And Classified As:–

Concentrated Motor Windings

• All the Windings Turns are twisted Motor Winding Together in an arrangement to frame one multi-turn loop.

• The All Motor winding coil turns have a similar attractive hub

• Examples of concentrated windings are – Field windings for notable shaft coordinated machines – D.C. machines – Primary and optional windings of a transformer

Distributed Motor Windings.

• All the Motor Winding Turns are organized in a few full-pitch or partial pitch To Coils.

• These Windings Coils loops are then housed in the openings spread around the air-hole fringe to frame stage or commutator winding

•The Examples of circulated windings are – Stator and rotor of acceptance machines – The armatures of both coordinated and D.C. machines

Armature windings, all in all, are ordered under two fundamental heads, specifically,

Closed Motor Winding.

• There is a shut way as in on the off chance that one beginnings from any point on the winding and crosses it, one again arrives at the beginning stage from where one had begun

• Used uniquely for D.C. machines and A.C. commutator machines

Open Motor Winding.

• Open Motor windings end at appropriate number of slip-rings or terminals

• Used uniquely for A.C. machines, as coordinated machines, acceptance machines, and so forth

What is Armature Winding?

There are 2 types of windings:

1. Field winding

2. Armature Winding.

What Is Field Winding?

Field Coil Winding On poles core which is on the stator body. These are always concentrated type. The field coil is mostly used on Generator sets Mixer Grinder Alternators And all types of Armature Based Field Coils.

What Is Armature Winding?

Armature winding On rotor on the motor may be simplex or multiplex and lap or wave connected. This is mostly used in Alternator, Generator Set, Mixer Grinder, and Dc Motor.

In Mixer Grinder Coil Winding Armature and Field Coils work together and running with both makes this motor very high speed. Like above 16000 Rpm Per Minutes.

In AC (Synchronous ) Motor.

3-Phase Star or Delta Connection connected on the stator [ Armature Winding ] supplied by 3 phase may be concentrated or distributed (usually preferred). Rotor (field ) has concentrated in salient pole type and distributed in cylindrical type supplied by DC supply.

On Ac Supply Induction Motor.

On AC Supply The Three Phase Induction Motor (star or delta connected) distributed winding on the stator and wound rotor. In C squirrel cage rotor, short-circuited copper bars are used.

Whats Is Dc Motor Winding.

They generally have two winding’s the field winding and the armature winding. The armature winding may be lap or wave wound depending if it is low voltage and high current or high voltage and low current respectively.

Dc motor is a rotating machine which converts electrical energy in to mechanical energy

Series Wound Dc Motor.

When the Field Coil Winding and Armature Winding are Connected in Series The Motor is Referred To as A Series Winding Dc motor. Armature and Field Coil Connection in Series Means The Current Through The Field Coil Winding and Armature Winding are Same and Equal.

Which Allows the Motors to draw a Significant Amount of the Current. Torque is Proportional to the Square Of Current. So, in that case, the Motors are able to Produce Very High Torque, When the motor take Startup.

Single Phase And Three Phase Motor Winding.

There are Two Types Of Motor Windings Normally used.

- Single Phase Motor Winding.

- Three Phase Motor Winding.

What is Single Phase Motor Winding?

The single-phase motor windings are base on Induction Motor. They are always working Together with Motor Winding, Capacitor, Clutch Plates, And The Capacitor is also used Two Types.

Types Of Capacitor?.

- Running Capacitor.

- Starting Capacitor.

In a single-phase motor, two types of capacitors are used on the motor, one is the running capacitor and the other is the starting capacitor.

The starting capacitor’s job is to start the motor only and only after that it disconnects from the motor.

And the running capacitor works with the motor as long as the motor runs.

And Here another thing that is noted is that Running and Starting Capacitors are Only used in single-phase motor and this capacitor is never used in a Three-Phase Induction Motor.

The single Phase motor Mostly based on two types of Motor winding and mostly install four coils in its Running Windings and also Installed Four Coils in its station winding. Normally Single phase motor is working with Two Types of Winding.

- Running Winding.

- Starting Winding.

The Running winding is used For Main Windings and the starting winding Purpose is only to start the motor and some motor its will be disconnected.

Single Phase Motor Winding Video.

Three Phase Motor Winding.

A Three-phase motor windings work mostly on two like motor stator and motor rotor.

The Capacitors are never used in The Three Phase Motor. This motor is supplied with three phases of input, all three phase input supply wires are of the same voltage is like220 volts and 440 volts.

And this motor operates on star and delta connections. Motors of 1Hp to 3Hp power operate mostly on star winding and motors above The Three hp are connected by a delta connection.

Motors above 5 hp are driven first on a star connection and later in delta with the help of a motor starter.

How To Run 3 Phase Motor On Single Phase Supply.

Three phase motor can be run on single phase supply if you want to run it only for testing then you will need a post which will be a starting capacitor which will be worth 80-100,100-120,200-250. You have to install the capacitor until the motor catches its full speed as soon as the motor catches full speed, you have to immediately remove the capacitor.

And where it is important to note that this work is done to test the winding of the motor only and only.

This work is mostly done with a Small Electric Motor that can go from 1hp to 5hp with a motor of more than 10 hp. If you want to run a 3 phase motor on a 2 phase double supply, then you have to take a shunt capacitor like You all know that the main supply coming from the back comes with 3 wires, out of the three, the input supply coming from the motor has to be connected to the motor.

And with one wire left, one wire of shunt capacitor is connected and another wire of shunt capacitor is joined with one winding motor.

Top Electric Motor Manufacturers Globally price and Buying Guide.

Major player in the market Are .

- ABB LTD.

- ARC SYSTEM.

- CROMPTON GREAVES LIMITED.

- EMERSON ELECTRIC COMPANY.

- BROOK CROMPTON UK LIMITED.

- REGAL BELOIT CORP.

- SIMENS AG.

- BALDOR ELECTRIC COMPANY.

- FRANKLIN ELECTRIC COMPANY.

- JOHNSON ELECTRIC HOLDING

- KIRLOSKAR

- ROBERT BOSTCH.

Three Phase Motor On Single Phase Supply Video Watch Here.

What is the motor winding?

It is a conductive wire, that is situated in a circle design that conveys electrical flow. At the point when a current-conveying transmitter is orchestrated along these lines, an attractive field is created through the escape clause, and the more circles you make with the wire, (the more “windings”) the more grounded the attractive field.

What Are The Types Of Windings?

- Motor Winding.

- Stator Winding.

- Wave Winding.

- Lap Winding.

How To Calculate Motor Winding Data?

In my opinion it is not possible to Calculate The 100% Right winding data.bcz its depends on so many factors like.

- Varios countries

- Different Contries Different input voltage supply

- Depend on Stator types.

- Stator Size Core Length.

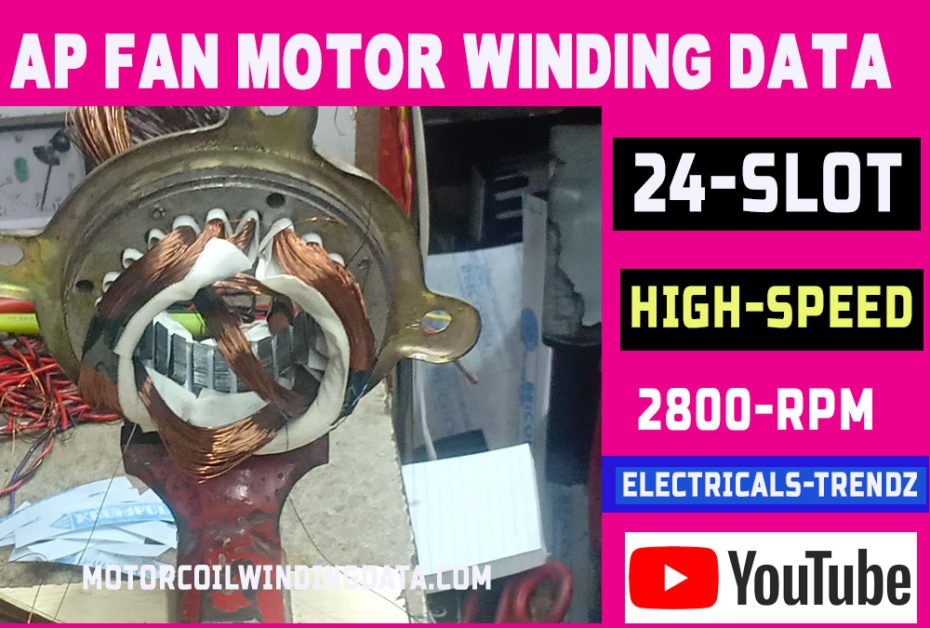

- Motor Slots.

- Stator Inner Diameter ,Outer Diamere.

- Frequency

- Duty Cycle.

- Kind Of Cooling.

- Allowable Temprature Rise

- Slot Size and Many More Thing.

But After all There are one Machanical Formula.

HP x 5250

RPM—-HP =TORQUE x RPM —–RPM=120 x FREQUENCY.

No. of Poles

5250

How To Check Motor Winding?

Normally we can check motor winding with series Lamp and Multimeter.

first of all check motor winding continity.if the motorn is on single phase you need to check both winding like running winding and the starting winding.

if your motor is Three speed then you need to check three wirs continity.

how to run three phase motor in single phase?

Three phase motor can be run on single phase supply if you want to run it only for testing then you will need a post which will be a starting capacitor which will be worth 80-100,100-120,200-250. You have to install the capacitor until the motor catches its full speed as soon as the motor catches full speed, you have to immediately remove the capacitor.

In this video you can easily make the connection of run three phase motor in single phase?